What makes a keyboard sustainable?

Two things, mainly:

Our keyboards are made in Taiwan by people who are employees, not contractors. People who get overtime, benefits, and paid holidays. That’s why around Chinese New Year our lead times always go up — because the people making the board get to spend time with their families.

They are made in an office building, not a factory. The conditions are good, and it is highly skilled labor with commensurate pay.

We include a two-year warranty with each of our keyboards. Many companies can say that. But what happens when you try to act on this warranty — when push comes to shove, and something goes wrong with the product? That’s when you find out if a company means what it says.

Most companies make you jump through hoops. Fill out forms, send out your product, wait several weeks for a replacement. We don’t. When something goes wrong with your board, we provide fast service and excellent communication, every time.

A keyswitch is a moving part. In a mechanical keyboard with dozens of keyswitches, one of these would obviously be the first to go. When a keyswitch goes, it usually begins exhibiting “chatter” — you press it once and get a few keystrokes, or no keystrokes at all.

With most other keyboards, you’re going to have to buy a whole new board. With ours, you just pop out the keyswitch and plop a new one in, no soldering required. And these keyswitches are industry-standard parts — Cherry-compatible and Kailh Choc keyswitches. These are both available from third parties all over the world, and with Cherry-compatible switches, they have been for decades now.

So if years down the road one of your keyswitches starts acting up, it’s easy to fix on your own.

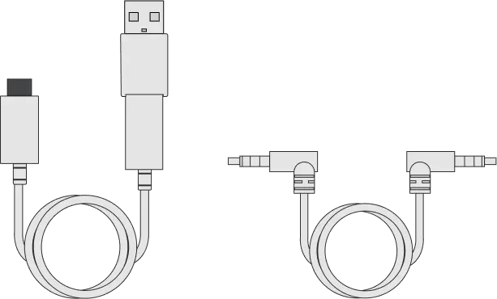

Many other keyboards have cables that come right out of the housing. Meaning, you don’t get a jack in the body of the keyboard, but just a cable that snakes out. With time and use, that cable gets bent over and over, and is very prone to breaking exactly where it connects to the body of the keyboard.

This is easy to solve: Use a jack! And that’s exactly what we did. We use a standard USB jack on the board, and include a high-quality cable — but you can swap out that cable at any time. The same goes for the Moonlander’s interconnect cable: That is an industry-standard 3.5mm TRRS cable (“audio cable”), with a jack on each half of the board.

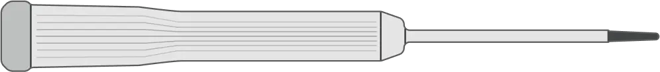

Many modern consumer devices are notoriously difficult to open. Whoever makes them does not want you poking around inside. They implement an arsenal of techniques to keep you out: weirdly-shaped screws, fragile clips, tough adhesives, and more.

With our boards, there’s none of that. Just Philips screws, and that’s it. No clips, no glue, no nonsense keeping you out.

So if you do need to open up one of our keyboards at any point in the future once it’s out of warranty, it’s easy and straightforward to do, and you can close it right back up again when you’re done repairing or modifying it.

The microcontroller powering your microwave oven or computer monitor is a black box. There’s software running on it — firmware, to be exact — but you’ll never know what it is, much less be able to modify it.

Our keyboards buck this trend, again. They run on open-source firmware called QMK. The entire source code that’s running on our keyboard is freely available on GitHub. You can compile the firmware locally, and will be able to do so even if our company ever goes out of business. You can audit the code, modify it, and improve it to your heart’s content — it is yours.

The Bottom Line:

All of these decisions combine to make our keyboards last a long, long time. We did everything in our power to make sure our keyboards serve you for many years, thus making them sustainable. Buy one good keyboard — not ten cheap ones that end up in the landfill.